RBSIC / SSIC TUBE

Silicon carbide (SiC) products are a category of materials and components that are made from silicon carbide, a compound of silicon and carbon. Silicon carbide is a hard and durable material with excellent thermal, mechanical, and electrical properties. It is used across in many challenging industrial applications. Some common silicon carbide products include. Their robust properties make them ideal for use as mechanical components and wear parts that are specified in applications such as but not limited to:

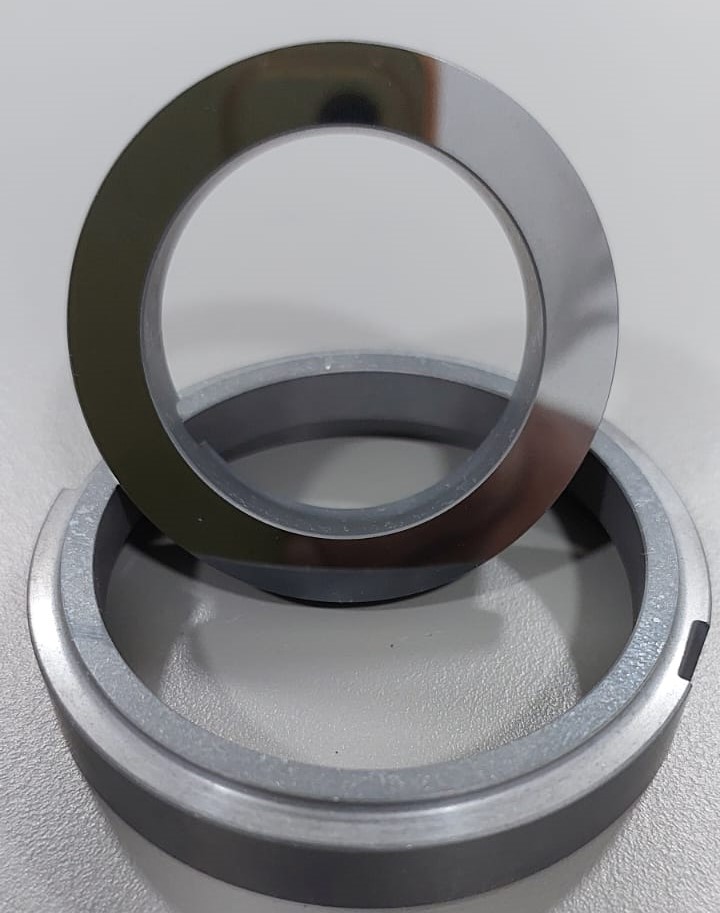

These are used in Oil Refineries, Petrochemical plants, Fertilizer Plants, and Drugs/Pharmaceutical Industries. Mechanical seal rings are developed to withstand high temperature, high pressure & highly corrosive chemical attack. DTEC manufactures Rings in various shapes like Flat Ring, DA type, T-shape, L-shape and in shapes as per customers requirement.

Application :

- Centrifugal pumps

- Submersible pumps

- Compressors

- Mixers and steam joints

- Gear pumps

- Propulsion shaft sealing

- High temperature and pressure applications

- Abrasive and aggressive fluid applications

- Mechanical seals for circulating pumps with limited dry running capability

- Bearings for circulating pumps

- Speciality pumps for handling corrosive and abrasive fluids

- Bearings for electric water pumps used in electric and/or hybrid cars

Desirable characteristics include:

- Superior wear resistance with low friction

- High-temperature capabilities

- Wide-ranging compatibility with other materials

- High thermal conductivity

- Outstanding thermal shock resistance

- Superior corrosion resistance, especially in alkali environments

Features :

| Reaction Bonded Silicon Carbide(RBSIC) | High wear resistance |

| Thermal shock resistance | |

| High modulus | |

| Sintered Silicon Carbide(SSIC) | High hardness and strength |

| High-temperature resistance | |

| High modulus | |

| Chemical resistance |